DIY Stainless Tumbler

39 posts

• Page 1 of 2 • 1, 2

DIY Stainless Tumbler

DIY Stainless Tumbler

I'm thinking of upgrading to stainless steel tumbler. Because I'm a tight arse and enjoy tinkering I want to make it myself. The rough plan at the moment is to use a a bucket (approx 5L I'm thinking), make a frame with a couple of castor wheels to spin the front of the bucket, mount a bolt through the bottom of the bucket which would attach to the motor.

In terms of a motor I'm thinking I'd repurpose either a windscreen wiper motor or desk fan motor. Do you reckon this motor would have enough power for the job? When full the bucket would probably be around 5kg.

http://www.bunnings.com.au/moretti-15cm ... n_p4440731

Any suggestions are appreciated

In terms of a motor I'm thinking I'd repurpose either a windscreen wiper motor or desk fan motor. Do you reckon this motor would have enough power for the job? When full the bucket would probably be around 5kg.

http://www.bunnings.com.au/moretti-15cm ... n_p4440731

Any suggestions are appreciated

.177, .22lr, .22-250R, 2x .308W, .30-30W, 7.62x54r, 8x56r, 9x19, .357 Mag, 12GA

-

Baldrick314 - Staff Sergeant

- Posts: 980

- New South Wales

Re: DIY Stainless Tumbler

There are a few ideas on this site ,but you will find everything from tumbler speed ratios and all the know how on this

http://castboolits.gunloads.com/forum.php

Use the advanced search or just scroll through the reloading section. In the swaging forum there are some plans as well as they have to clean all the brass before swaging it into jackets. I did not build mine but use the Model B. If I was going to improve it I would put in roller bearings instead of plain nylon bearings

Bill

http://castboolits.gunloads.com/forum.php

Use the advanced search or just scroll through the reloading section. In the swaging forum there are some plans as well as they have to clean all the brass before swaging it into jackets. I did not build mine but use the Model B. If I was going to improve it I would put in roller bearings instead of plain nylon bearings

Bill

Swaging your own projectiles is the ultimate in flexibility.

- Bills Shed

- Corporal

- Posts: 433

- Tasmania

Re: DIY Stainless Tumbler

Thank you mate, I'll have a look through

.177, .22lr, .22-250R, 2x .308W, .30-30W, 7.62x54r, 8x56r, 9x19, .357 Mag, 12GA

-

Baldrick314 - Staff Sergeant

- Posts: 980

- New South Wales

Re: DIY Stainless Tumbler

The motor relys on the fan to keep it cool to will just over heat. U need a motor with an internal fan.

The greatest invention in the history of man is beer.

https://youtu.be/2v3QrUvYj-Y

Member. SFFP, Shooters Union.

SSAA, the powerful gun lobby.

Hunt safe.

https://youtu.be/2v3QrUvYj-Y

Member. SFFP, Shooters Union.

SSAA, the powerful gun lobby.

Hunt safe.

-

Oldbloke - Field Marshal

- Posts: 11293

- Victoria

Re: DIY Stainless Tumbler

Oldbloke wrote:The motor relys on the fan to keep it cool to will just over heat. U need a motor with an internal fan.

Thanks Oldbloke. Any suggestion on where to pick up an appropriate motor on the cheap?

.177, .22lr, .22-250R, 2x .308W, .30-30W, 7.62x54r, 8x56r, 9x19, .357 Mag, 12GA

-

Baldrick314 - Staff Sergeant

- Posts: 980

- New South Wales

Re: DIY Stainless Tumbler

bentaz wrote:You'll need a motor thats geared down a whole bunch.

Ebay is a good place to find them

http://pages.ebay.com/link/?nav=item.vi ... 19&alt=web

Something like that but you'll need to work out your speed and torque requirements

Is there some kind of formula or calculator for working out your power needs? Mechanics isn't my strongest suit

Thanks for the link

.177, .22lr, .22-250R, 2x .308W, .30-30W, 7.62x54r, 8x56r, 9x19, .357 Mag, 12GA

-

Baldrick314 - Staff Sergeant

- Posts: 980

- New South Wales

Re: DIY Stainless Tumbler

If you have a look at the cast bullet web site there is a thread there with all the maths and drawings plus examples of the drive train. You do not need a gearbox as the pulleys will give you the reduction and a small 1/3 hp single phase motor is more than enough to do the job.

Bill

Bill

Swaging your own projectiles is the ultimate in flexibility.

- Bills Shed

- Corporal

- Posts: 433

- Tasmania

Re: DIY Stainless Tumbler

Swaging your own projectiles is the ultimate in flexibility.

- Bills Shed

- Corporal

- Posts: 433

- Tasmania

Re: DIY Stainless Tumbler

Cheers mate, I searched that website earlier but on my phone it only returned a half dozen results. Will do some reading.

.177, .22lr, .22-250R, 2x .308W, .30-30W, 7.62x54r, 8x56r, 9x19, .357 Mag, 12GA

-

Baldrick314 - Staff Sergeant

- Posts: 980

- New South Wales

Re: DIY Stainless Tumbler

After looking around I want to try to have the motor attach directly to the bucket rather than have a pulley system, mainly because this would be simpler for me to make and I can buy a motor rated for the speed I want the bucket to turn rather than do conversions.

I found this website http://www.precisionmicrodrives.com/tec ... plications

Which gave me a formula for working out the load a motor can lift (formula 2). Based on a rough estimate at the moment of 10kg maximum weight in the bucket the result I calculated using that formula says that I need a motor capable of

.294Nmm or 2.99kg/cm. Is this correct or have I ballsed the math up?

If I have got those figures right would this motor then suffice to drive the bucket?

http://pages.ebay.com/link/?nav=item.vi ... 46&alt=web

I found this website http://www.precisionmicrodrives.com/tec ... plications

Which gave me a formula for working out the load a motor can lift (formula 2). Based on a rough estimate at the moment of 10kg maximum weight in the bucket the result I calculated using that formula says that I need a motor capable of

.294Nmm or 2.99kg/cm. Is this correct or have I ballsed the math up?

If I have got those figures right would this motor then suffice to drive the bucket?

http://pages.ebay.com/link/?nav=item.vi ... 46&alt=web

.177, .22lr, .22-250R, 2x .308W, .30-30W, 7.62x54r, 8x56r, 9x19, .357 Mag, 12GA

-

Baldrick314 - Staff Sergeant

- Posts: 980

- New South Wales

Re: DIY Stainless Tumbler

I did not do the maths on the motor or torque required. It does look a bit small and light duty to turn a 5 kg bucket even if it is sitting on rollers. The actual motor is doing over 3000 rpm. It may be fine, but with no cooling fan and running so fast I do not think it would have much of a duty cycle. I gather that you will have a friction wheel coupling to the bucket or similar, so the bucket can be removed for cleaning/ filling. If so it will need to be on a slight incline. If this is the case, I Do not think the gearbox has thrust bearings designed for the load. It all depends on your design.

Let us know how it goes, it may work perfectly. At the price of the motor you would mot be loosing much.

Bill

Let us know how it goes, it may work perfectly. At the price of the motor you would mot be loosing much.

Bill

Swaging your own projectiles is the ultimate in flexibility.

- Bills Shed

- Corporal

- Posts: 433

- Tasmania

Re: DIY Stainless Tumbler

I've had a breakthrough. I was initially hesitant to go the route of a windscreen wiper motor because I didn't have anything to convert DC to AC.

After speaking to a friend of mine this morning who's an engineer he told me that's the best way to go and that he had a transformer that would suit my application. He also said that the only torque issues I'd have would be on startup, once it starts rolling the weight will sustain motion with little effort from the motor.

This afternoon I'll head to the wreckers to pick up a motor, already have the bucket, castor wheels and wood to make a frame. I'll order some stainless pins tonight and pick up the transformer before the end of the week and I should be ready to go.

After speaking to a friend of mine this morning who's an engineer he told me that's the best way to go and that he had a transformer that would suit my application. He also said that the only torque issues I'd have would be on startup, once it starts rolling the weight will sustain motion with little effort from the motor.

This afternoon I'll head to the wreckers to pick up a motor, already have the bucket, castor wheels and wood to make a frame. I'll order some stainless pins tonight and pick up the transformer before the end of the week and I should be ready to go.

.177, .22lr, .22-250R, 2x .308W, .30-30W, 7.62x54r, 8x56r, 9x19, .357 Mag, 12GA

-

Baldrick314 - Staff Sergeant

- Posts: 980

- New South Wales

Re: DIY Stainless Tumbler

i was gunna make one of them too but then i realized i wanted to do all my brass at one time and made this

-

deye243 - Second Lieutenant

- Posts: 2243

- Victoria

Re: DIY Stainless Tumbler

Holy sheet! Is that for all your brass or all your suburb's brass???

Last edited by Gwion on 17 Feb 2016, 7:53 am, edited 1 time in total.

-

Gwion - Colonel

- Posts: 3978

- -

Re: DIY Stainless Tumbler

That's awesome Deye! The most I ever get in a batch is about 150-200 cases so any bigger would be overkill for me

.177, .22lr, .22-250R, 2x .308W, .30-30W, 7.62x54r, 8x56r, 9x19, .357 Mag, 12GA

-

Baldrick314 - Staff Sergeant

- Posts: 980

- New South Wales

Re: DIY Stainless Tumbler

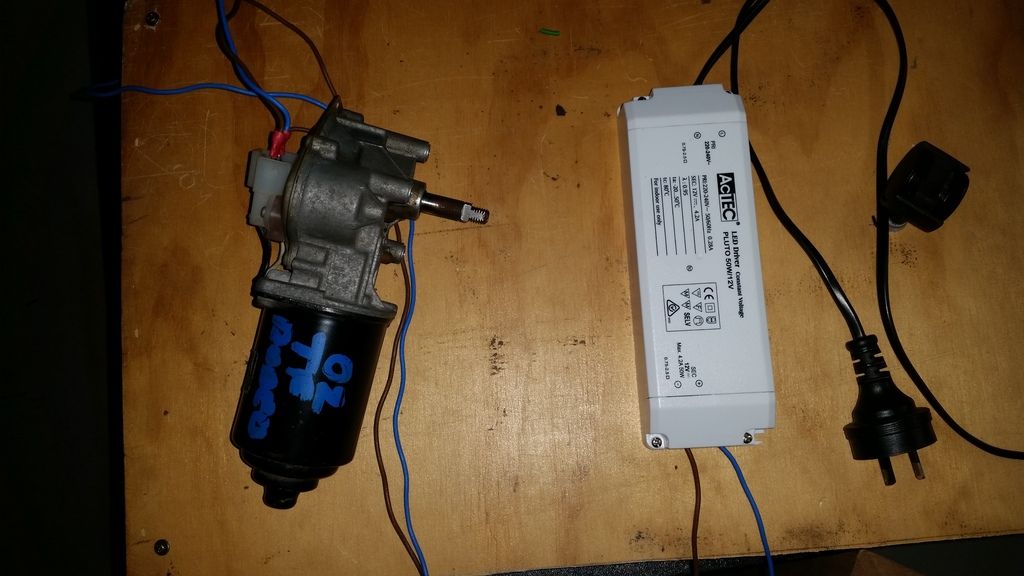

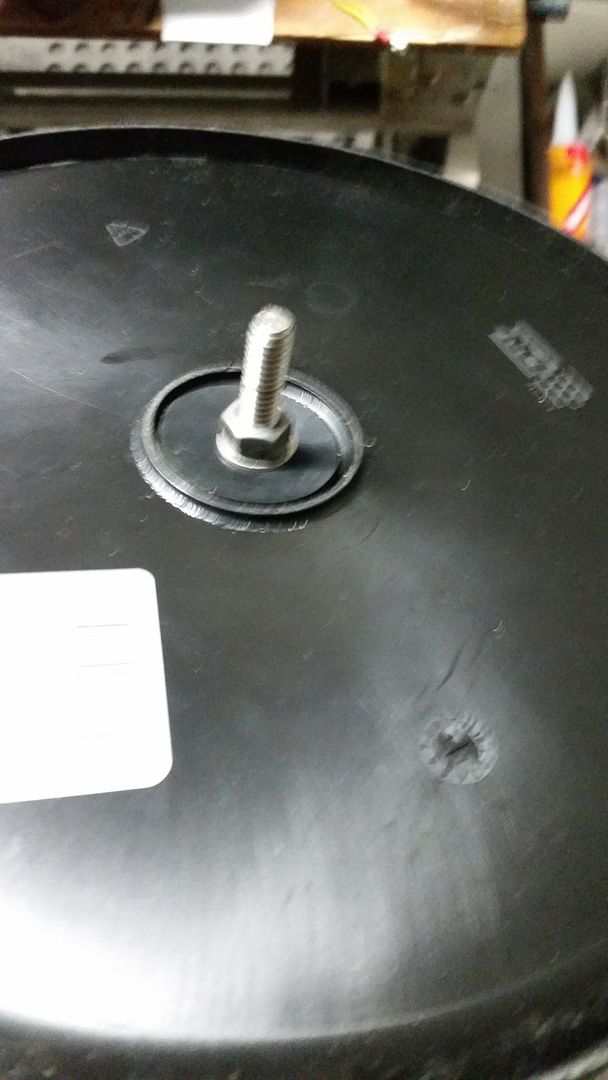

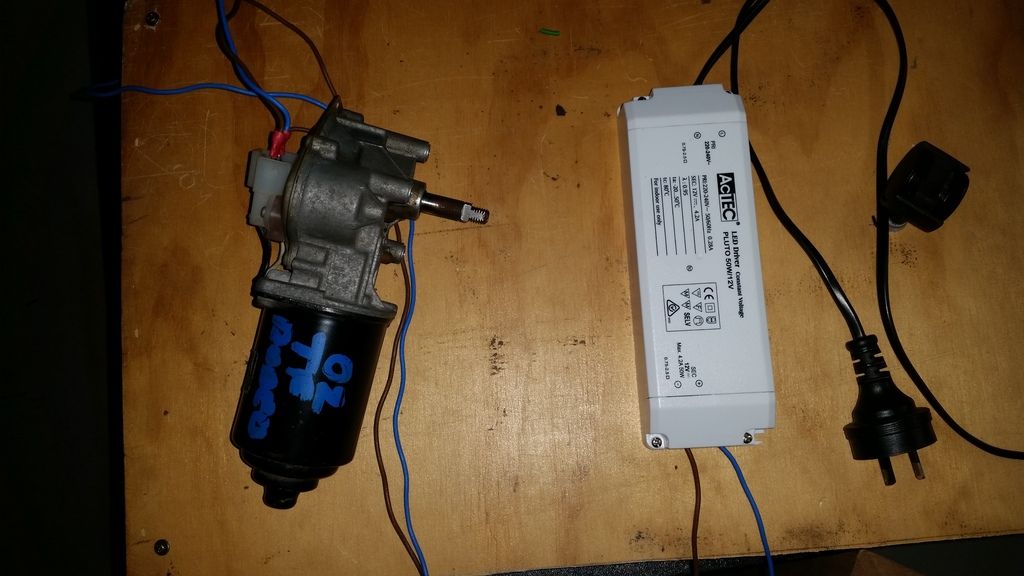

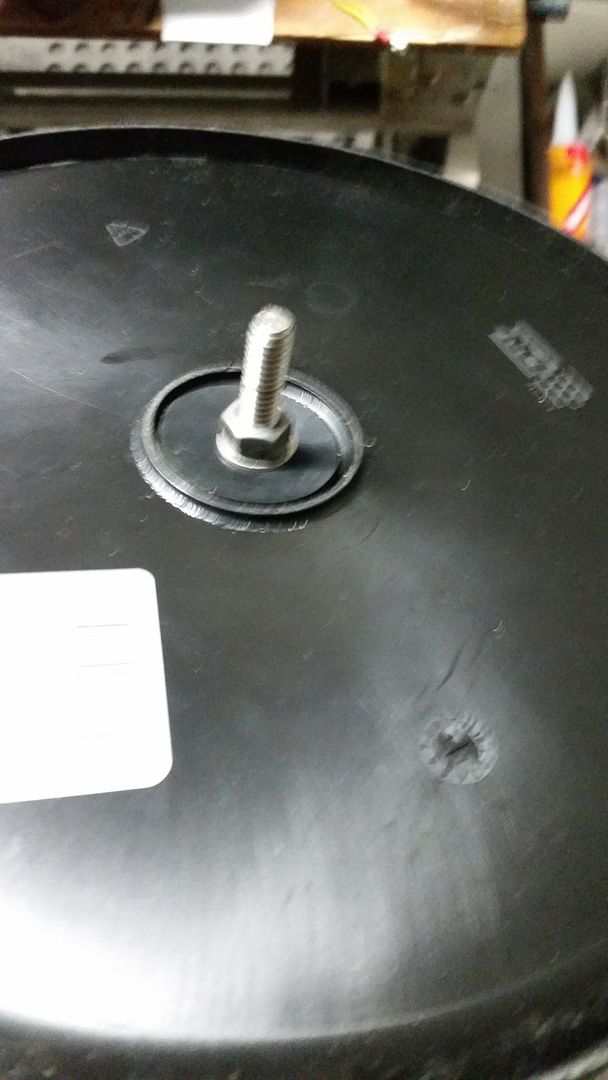

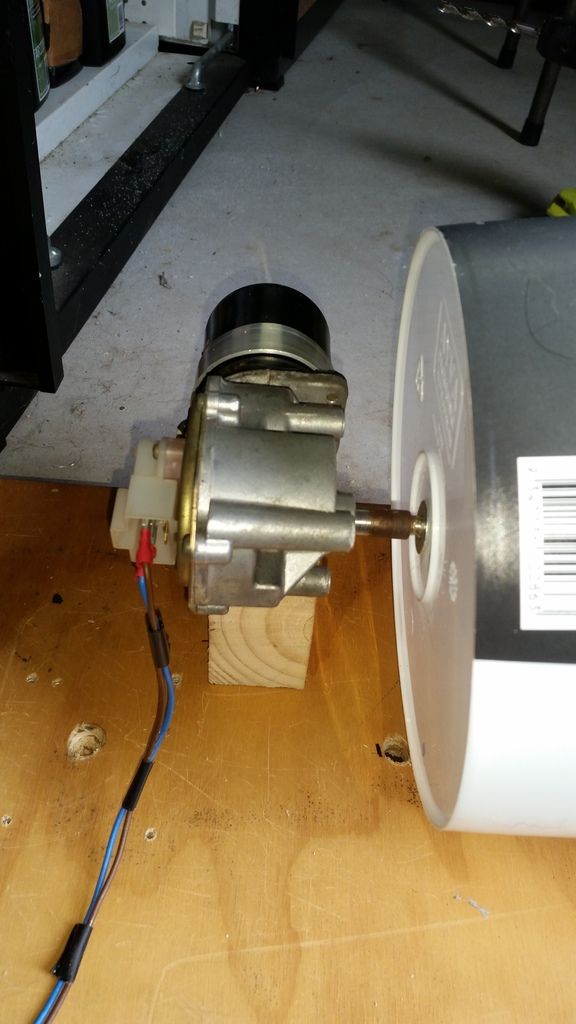

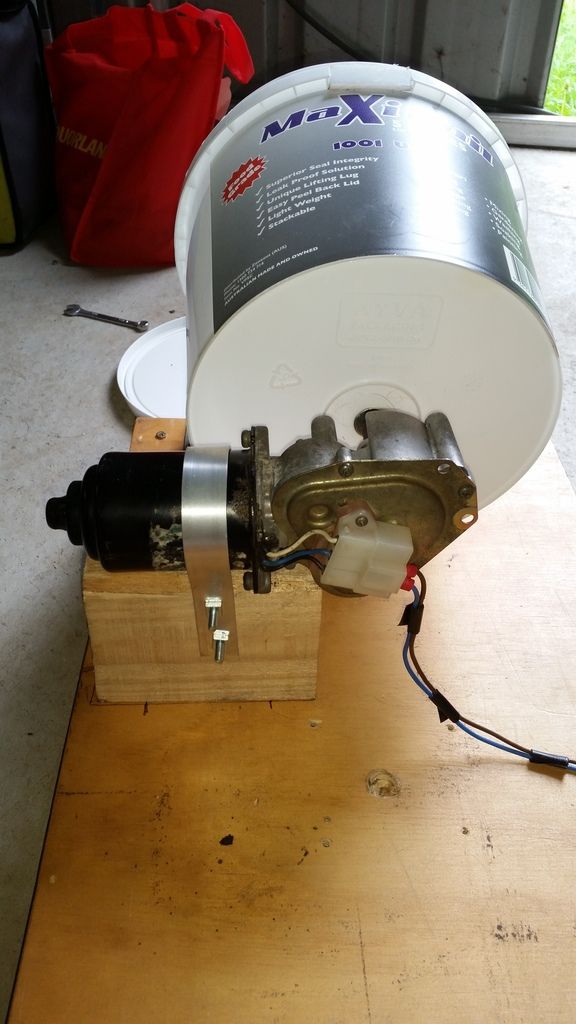

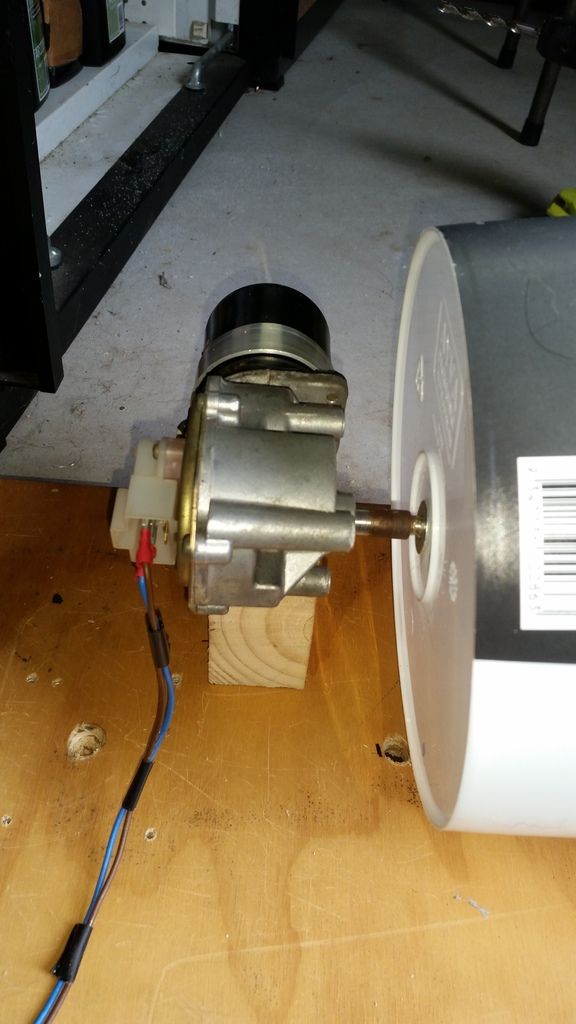

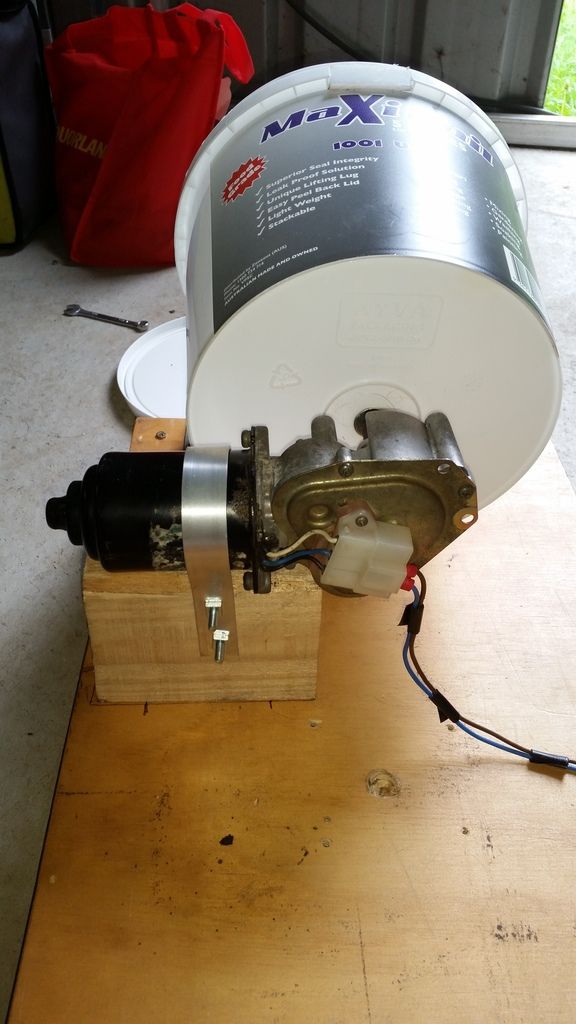

Bit of an update. I've now made the frame, wired up the motor and attached a bolt to the bucket. Here's a couple pics of what I've got so far:

The motor and transformer. The wires will be shortened once everything is mounted up.

The frame. Two wheels at front support the front of the bucket and help it rotate, the rear holds the ass end up to avoid placing excess stress on the motor.

Underside of frame with rubber feet.

Bolt through the bottom of bucket. It's hard to see but there's a rubber grommet on there and on the inside, I'll also silicon around them to provide a seal.

Length of stiff polymer rod used to connect the bolt and motor. It's been threaded and will mate the two parts together like a drive shafts.

Some shaped plastic I found. I'll attach a couple of these to the inside of the bucket to act as fins to agitate the brass and media.

I've still got to build a frame to mount the motor to so it's the correct height behind the bucket and then it's pretty much ready to go.

The motor and transformer. The wires will be shortened once everything is mounted up.

The frame. Two wheels at front support the front of the bucket and help it rotate, the rear holds the ass end up to avoid placing excess stress on the motor.

Underside of frame with rubber feet.

Bolt through the bottom of bucket. It's hard to see but there's a rubber grommet on there and on the inside, I'll also silicon around them to provide a seal.

Length of stiff polymer rod used to connect the bolt and motor. It's been threaded and will mate the two parts together like a drive shafts.

Some shaped plastic I found. I'll attach a couple of these to the inside of the bucket to act as fins to agitate the brass and media.

I've still got to build a frame to mount the motor to so it's the correct height behind the bucket and then it's pretty much ready to go.

.177, .22lr, .22-250R, 2x .308W, .30-30W, 7.62x54r, 8x56r, 9x19, .357 Mag, 12GA

-

Baldrick314 - Staff Sergeant

- Posts: 980

- New South Wales

Re: DIY Stainless Tumbler

Could you put the link for where you got your S/S pins from please. I found some on eBay and I'm seeing if I could get it any cheaper.

- zobster

- Lance Corporal

- Posts: 221

- Tasmania

Re: DIY Stainless Tumbler

zobster wrote:Could you put the link for where you got your S/S pins from please. I found some on eBay and I'm seeing if I could get it any cheaper.

I bought a pound of them on ebay for $20. That was before I realized how much media I'd actually need. For the size bucket I'm using I should need around 5 pounds. I'm actually considering buying a roll of stainless wire and cutting my own. You can get 15m for about $16 at bunnings and I'll just spend a couple nights cutting it while watching TV.

Otherwise you could purchase from aussie sapphire. They have 5 pounds of media and burnishing compound for $85 plus post

http://aussiesapphire.com.au/index.php? ... ts_id=2876

.177, .22lr, .22-250R, 2x .308W, .30-30W, 7.62x54r, 8x56r, 9x19, .357 Mag, 12GA

-

Baldrick314 - Staff Sergeant

- Posts: 980

- New South Wales

Re: DIY Stainless Tumbler

I'm leaning towards the cutting route, it seem the cheapest

- zobster

- Lance Corporal

- Posts: 221

- Tasmania

Re: DIY Stainless Tumbler

Yeah that's my thoughts too, it's a huge difference in price for just a little labour. When I buy the wire I'll weigh it and see how much each roll is and how many I'll need to make the weight. I reckon 1 or maybe 1.5 rolls should do it

.177, .22lr, .22-250R, 2x .308W, .30-30W, 7.62x54r, 8x56r, 9x19, .357 Mag, 12GA

-

Baldrick314 - Staff Sergeant

- Posts: 980

- New South Wales

Re: DIY Stainless Tumbler

Your mate is right, stuff all torque needed as the gearing will convert the revs to more torque. You seem to have solved the moter issue.

The greatest invention in the history of man is beer.

https://youtu.be/2v3QrUvYj-Y

Member. SFFP, Shooters Union.

SSAA, the powerful gun lobby.

Hunt safe.

https://youtu.be/2v3QrUvYj-Y

Member. SFFP, Shooters Union.

SSAA, the powerful gun lobby.

Hunt safe.

-

Oldbloke - Field Marshal

- Posts: 11293

- Victoria

Re: DIY Stainless Tumbler

Gwion wrote:Holy sheet! Is that for all your brass or all your suburb's brass???

If he's too tired at the end of a big day to wash himself he just jumped in and has a snooze while it goes around for half an hour.

Comes out sparkling clean

-

lole - Corporal

- Posts: 359

- New South Wales

Re: DIY Stainless Tumbler

Yesterday I attached the fins to the inside of the bucket and sealed everything up with silicon. I also cut the shaft down to the right size and finished threading it.

I ran into a problem with the transformer, it's the right voltage but doesn't create enough amps to power the motor reliably so I'm in search of a power source. For the time being I'm thinking an old car battery. Should be finishing the mount for the motor on friday and I'll be ready to run.

Went to bunnings yesterday and bought the stainless steel wire, got it home and two rolls add up to roughly a pound so it's nowhere near as cost effective as I thought. I'm going to use the 2 pounds of media I currently have and run the tumbler at a lower capacity since I usually only have around 200 pistol cases or 50 rifle cases at any time. If I were starting from scratch knowing what I know now I'd go with the Aussie Sapphire kit I posted above. Also cutting up the steel wire is a really s**t job

I ran into a problem with the transformer, it's the right voltage but doesn't create enough amps to power the motor reliably so I'm in search of a power source. For the time being I'm thinking an old car battery. Should be finishing the mount for the motor on friday and I'll be ready to run.

Went to bunnings yesterday and bought the stainless steel wire, got it home and two rolls add up to roughly a pound so it's nowhere near as cost effective as I thought. I'm going to use the 2 pounds of media I currently have and run the tumbler at a lower capacity since I usually only have around 200 pistol cases or 50 rifle cases at any time. If I were starting from scratch knowing what I know now I'd go with the Aussie Sapphire kit I posted above. Also cutting up the steel wire is a really s**t job

.177, .22lr, .22-250R, 2x .308W, .30-30W, 7.62x54r, 8x56r, 9x19, .357 Mag, 12GA

-

Baldrick314 - Staff Sergeant

- Posts: 980

- New South Wales

Re: DIY Stainless Tumbler

Make sure with your wire it's either small enough to easily pass through or big enough to not fit and get stuck in the flash holes.

-

TheDude - Corporal

- Posts: 313

- Queensland

Re: DIY Stainless Tumbler

TheDude wrote:Make sure with your wire it's either small enough to easily pass through or big enough to not fit and get stuck in the flash holes.

The pre-cut media I bought was 1mm thick and the wire I bought to cut was 1.6mm. From memory most flash holes are around .6mm so shouldn't be an issue, thanks for the advice though

.177, .22lr, .22-250R, 2x .308W, .30-30W, 7.62x54r, 8x56r, 9x19, .357 Mag, 12GA

-

Baldrick314 - Staff Sergeant

- Posts: 980

- New South Wales

Re: DIY Stainless Tumbler

Any chance of a youtube to see this beast in action

300 Win Mag Fanboy

Tikka, Tikka, Tikka, BOOM!

Tikka, Tikka, Tikka, BOOM!

-

RDobber - Corporal

- Posts: 322

- Tasmania

Re: DIY Stainless Tumbler

now I have to make a small tumbler because I sold all but one of my centre fires I just have a 223 now and the LA101

I have 2500 cases but no way am I going to process that in one go I now just need a smaller tumbler for 200-300

I now just need a smaller tumbler for 200-300

at a time .

cheers D

I have 2500 cases but no way am I going to process that in one go

at a time .

cheers D

-

deye243 - Second Lieutenant

- Posts: 2243

- Victoria

Re: DIY Stainless Tumbler

Now that I'm shooting again I've revisited this little project. After having a failure last time I tried to run it I've changed my design to eliminate some of the flaws.

First up I went to a smaller bucket, approximately half the size of the the original one. I figured the average load that will be run through this will be 50 .308 cases or 100 9mm cases so the extra room isn't really necessary.

I glued two disruptor fins inside to keep the media and cases moving

The area that failed last time was a polymer rod I used to connect the motor to the bucket. I was originally planning to make a steel coupling to connect the two but didn't have the materials on hand so I've gone with just screwing a nut onto the driveshaft of the motor. There was very little meat there so I've only been able to fit a washer either side and no form of seal so this could give me issues when I add water but I'm going to see how it runs before I worry too much.

I gave it a dry run not long ago with approximately 75 308 cases and there were no issues. I'll keep testing with gradually more cases and maybe some media this afternoon/ night. First wet run will be tomorrow after the glue has had 24 hours to cure.

Hopefully if I can use a minimum of water everything will hold up and not leak too much.

First up I went to a smaller bucket, approximately half the size of the the original one. I figured the average load that will be run through this will be 50 .308 cases or 100 9mm cases so the extra room isn't really necessary.

I glued two disruptor fins inside to keep the media and cases moving

The area that failed last time was a polymer rod I used to connect the motor to the bucket. I was originally planning to make a steel coupling to connect the two but didn't have the materials on hand so I've gone with just screwing a nut onto the driveshaft of the motor. There was very little meat there so I've only been able to fit a washer either side and no form of seal so this could give me issues when I add water but I'm going to see how it runs before I worry too much.

I gave it a dry run not long ago with approximately 75 308 cases and there were no issues. I'll keep testing with gradually more cases and maybe some media this afternoon/ night. First wet run will be tomorrow after the glue has had 24 hours to cure.

Hopefully if I can use a minimum of water everything will hold up and not leak too much.

.177, .22lr, .22-250R, 2x .308W, .30-30W, 7.62x54r, 8x56r, 9x19, .357 Mag, 12GA

-

Baldrick314 - Staff Sergeant

- Posts: 980

- New South Wales

39 posts

• Page 1 of 2 • 1, 2