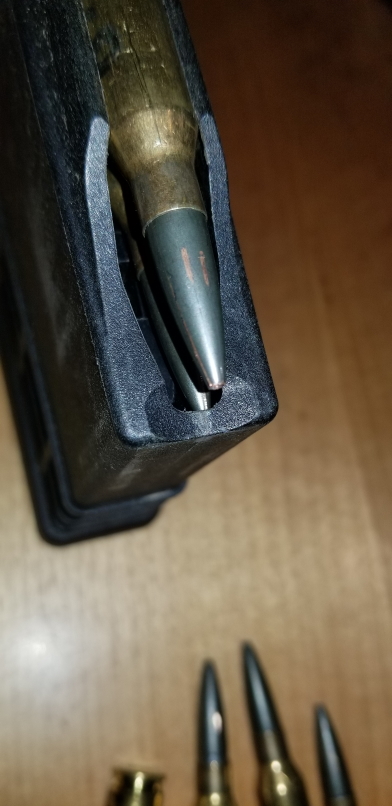

Loaded up eight rounds of 7mm-08 with the 130gn Outer Edge HP for testing.

- 20221220_212130b.jpg (232.08 KiB) Viewed 2545 times

- 20221220_212136b.jpg (224.15 KiB) Viewed 2545 times

- 20221220_215526b.jpg (199.45 KiB) Viewed 2545 times

The coating does indeed come off on your fingers, very grubby, and it scrapes off during feeding. I'm inclined to clean the crap off the rest of them. It's supposed to be a lube to reduce the pressure spike as the bullet slams into the lands.

One very strange thing about the design is that the bullet has a groove around the bearing surface. Reduces the diameter down to .278" over a length of about .150". Problem is that this groove, when seated to the standard 2.800" in 7mm-08 brass, is all inside the case mouth. The case neck is only about .250" long so there is all of .100" of case neck actually in contact with the bullet, all of it down at the bottom of the neck. This does not make for a tight fit in the case.

https://www.youtube.com/watch?v=3TJ4x6la-J4I did measure length to the lands (in the Ruger American) beforehand at 2.900", but as this is for hunting I want to stay at 2.800". They recommend .040"-.060" of jump so loading longer would give a better grip, but I need to seat about .150" longer to get the full length of the neck gripping the bullet. Cleaning the lube crap off will probably improve grip on the bullet as well.

Their load data is 2.783" CoaL but seating the bullets another .17" is not enough to get a grip on the bearing surface forward of the groove. It just pushes the bottom of the groove closer to the shoulder making it even more loose.

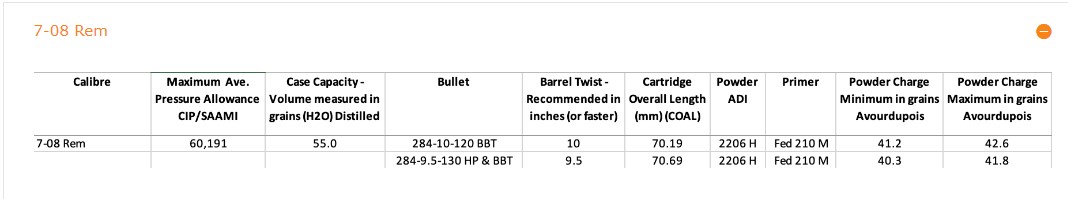

- Screenshot 2022-12-19 205508.jpg (38.27 KiB) Viewed 2545 times

I cycled them through the mag twice and they feed fine with nothing to indicate the bullet might get pushed deeper during feeding. I'll test shoot them and decide if it's an issue.

So far I'm less than impressed, especially compared to the Barnes TSX and TTSX bullets.