Casting boolits

48 posts

• Page 1 of 2 • 1, 2

Re: Casting boolits

No advice to offer sorry but keen as to see the result.

About time I got myself a lever. Interested in casting too...

About time I got myself a lever. Interested in casting too...

Mossberg MVP Varmint .223 Rem

Nikon Buckmaster 4.5-14x40

Howa 1500 Stainless .308 Win

Nikon Buckmaster 3-9x40

Nikon Buckmaster 4.5-14x40

Howa 1500 Stainless .308 Win

Nikon Buckmaster 3-9x40

-

buster - Private

- Posts: 89

- New South Wales

Re: Casting boolits

Well I bought 3kg of beeswax today. I'll be using this for the base for any lube recipes I try out. First one is simply equal parts beeswax and moly grease. Will see how it goes

Oh and Buster, here is an excellent source of info on casting bullets for starters like me:

http://www.lasc.us/Fryxell_Book_Contents.htm

Oh and Buster, here is an excellent source of info on casting bullets for starters like me:

http://www.lasc.us/Fryxell_Book_Contents.htm

-

von_klitzing - Lance Corporal

- Posts: 144

- Queensland

Re: Casting boolits

Black powder isn't far away from your testing program now!

There's still a few of Wile. E Coyote's ideas that I haven't tried yet.

-

Noisydad - Warrant Officer C1

- Posts: 1383

- Victoria

Re: Casting boolits

Don't listen to Noisy.

He'll turn you into an addict like him who spends his days huffing black powder smoke

He'll turn you into an addict like him who spends his days huffing black powder smoke

-

Lorgar - Second Lieutenant

- Posts: 2156

- Victoria

Re: Casting boolits

Well, did a great casting session today  all that research payed off! No hiccups (except I nearly melted the ingot mould on the oxy lol) but otherwise smooth sailing

all that research payed off! No hiccups (except I nearly melted the ingot mould on the oxy lol) but otherwise smooth sailing  will build up a good supply of clean ingots then will cast some 44 rounds

will build up a good supply of clean ingots then will cast some 44 rounds

Also, I highly recommend a temp controller! This one piece of kit is keeping the temps solid the entire session. It is definitely worth it's weight in gold.

Also, I highly recommend a temp controller! This one piece of kit is keeping the temps solid the entire session. It is definitely worth it's weight in gold.

-

von_klitzing - Lance Corporal

- Posts: 144

- Queensland

Re: Casting boolits

Happy days!  Wonder if the health benefits of bullet casting have studied? Given you're doing it at work I think that because of all that focused, deeply meditative, "man cave" time your productivity may have actually risen! I reckon a government grant could be acquired to study that!

Wonder if the health benefits of bullet casting have studied? Given you're doing it at work I think that because of all that focused, deeply meditative, "man cave" time your productivity may have actually risen! I reckon a government grant could be acquired to study that!

There's still a few of Wile. E Coyote's ideas that I haven't tried yet.

-

Noisydad - Warrant Officer C1

- Posts: 1383

- Victoria

-

Fujix - Private

- Posts: 81

- Victoria

Re: Casting boolits

Looks like you've got a little pyramid of silver there.

Planning for the apocalypse when everyone's bank accounts get reset?

Planning for the apocalypse when everyone's bank accounts get reset?

Dear Santa,

Please bring me a Desert Tactical Arms SRS-A1 Rifle in .338 Lapua Magnum.

I'll be good with it, I promise!

Please bring me a Desert Tactical Arms SRS-A1 Rifle in .338 Lapua Magnum.

I'll be good with it, I promise!

-

sarki - Lance Corporal

- Posts: 153

- New South Wales

Re: Casting boolits

What are the bits you're melting there?

Just all odds and ends made of lead are they?

Just all odds and ends made of lead are they?

Remington 700

another Remington 700

another Remington 700

-

meek - Private

- Posts: 50

- New South Wales

Re: Casting boolits

I've been melting down wheel weights from car tyre shops. I get about an hour before work and an hour at lunch to cast, but I have the pot running all day so I can pour between jobs too hehe. As long as the work gets done.

A carton of beer gets me a bucket of weights (the tyre joint estimates 25kg, I weighed it closer to 45kg lol) separate the zinc, steel and lead types, then smelt the lead weights using gas or electric pot. That one bucket produced 64 x 1 lb ingots

I'll pull the bullet molds out tomorrow morning and cast some boolits! Can't wait I have another full bucket to start working on now too...

I have another full bucket to start working on now too...

A carton of beer gets me a bucket of weights (the tyre joint estimates 25kg, I weighed it closer to 45kg lol) separate the zinc, steel and lead types, then smelt the lead weights using gas or electric pot. That one bucket produced 64 x 1 lb ingots

I'll pull the bullet molds out tomorrow morning and cast some boolits! Can't wait

-

von_klitzing - Lance Corporal

- Posts: 144

- Queensland

-

meek - Private

- Posts: 50

- New South Wales

Re: Casting boolits

Life happened last week so I got stuck in to casting some projectiles today and here's the result!

I'm pretty happy with that for my first session. I used a Saeco #445 (62445) 44 cal 220 grain SWCBB double cavity mould. Obviously not first class casts, but a good step in the right direction. I was able to read the signs of the lead once it was set to tell if I required more heat or less heat. It's always good to have an oxy torch on hand

So now I need to lube and size these bad boys. I'm not keen on the idea of pan lubing, so I thing I'll be putting them in a container for tumble lubing. Anyone have any other methods that could be easier or cleaner? Or better still, something I can DIY build to get the job done??

Will see how it goes. I'll post more pics of lubing later...

I'm pretty happy with that for my first session. I used a Saeco #445 (62445) 44 cal 220 grain SWCBB double cavity mould. Obviously not first class casts, but a good step in the right direction. I was able to read the signs of the lead once it was set to tell if I required more heat or less heat. It's always good to have an oxy torch on hand

So now I need to lube and size these bad boys. I'm not keen on the idea of pan lubing, so I thing I'll be putting them in a container for tumble lubing. Anyone have any other methods that could be easier or cleaner? Or better still, something I can DIY build to get the job done??

Will see how it goes. I'll post more pics of lubing later...

- VonKlitzing

- Recruit

- Posts: 3

- Queensland

Re: Casting boolits

You may not need to size them (depending on your barrel diam).

I don't size the .314 bullets for Lady Noisy's .32-20 Winchester coz it shoots way better groups than with sized bullets nor do I size the .415 bullets for my 40-65 Sharps (for the same reason).

You might need to slug your bore with a bullet cast from pure lead (that you can push down the barrel with a rod) and measure it to find the difference between your bullets and your barrel.

Lots of learned tomes say the bullets should be 2 thousandths of an inch bigger than bore diameter.

I don't size the .314 bullets for Lady Noisy's .32-20 Winchester coz it shoots way better groups than with sized bullets nor do I size the .415 bullets for my 40-65 Sharps (for the same reason).

You might need to slug your bore with a bullet cast from pure lead (that you can push down the barrel with a rod) and measure it to find the difference between your bullets and your barrel.

Lots of learned tomes say the bullets should be 2 thousandths of an inch bigger than bore diameter.

There's still a few of Wile. E Coyote's ideas that I haven't tried yet.

-

Noisydad - Warrant Officer C1

- Posts: 1383

- Victoria

Re: Casting boolits

ah, yes... like a studious erm, student, I slugged the bore prior to purchasing the molds. Max diameter readings I got were - Chamber: .429" Muzzle: .430"

I did however read that only .001" over was the cast diameter to aim for so I got a .430" mold. I guess that means my bullets shouldn't need to be sized then eh? Maybe it's even a bit on the small side?? Only one way to find out.

The only thing I can think of is removing the seam from the bullet? each bullet has a very small seam where the moulds join together, and are .002-.003" over in those spots.

Should I be sizing the bullets to get rid of this, or will the bullet still be seated centrally with it?

I think I'll size them to .430" to remove any high spots. Worst case is it does nothing I guess eh?

So lube, size, lube it is

Then on to loading them up.

I did however read that only .001" over was the cast diameter to aim for so I got a .430" mold. I guess that means my bullets shouldn't need to be sized then eh? Maybe it's even a bit on the small side?? Only one way to find out.

The only thing I can think of is removing the seam from the bullet? each bullet has a very small seam where the moulds join together, and are .002-.003" over in those spots.

Should I be sizing the bullets to get rid of this, or will the bullet still be seated centrally with it?

I think I'll size them to .430" to remove any high spots. Worst case is it does nothing I guess eh?

So lube, size, lube it is

Then on to loading them up.

-

von_klitzing - Lance Corporal

- Posts: 144

- Queensland

Re: Casting boolits

Hey Von,

Two forum accounts? Having problems with your first one?

Two forum accounts? Having problems with your first one?

See you on the firing line.

-

Aster - Moderator

- -

Re: Casting boolits

Noisydad wrote:Lots of learned tomes say the bullets should be 2 thousandths of an inch bigger than bore diameter.

Not saying there wrong... Something about that makes me uncomfortable knowing I'm sticking a bullet that's too big into a pipe then lighting a fire behind it

Henry .22LR Lever Action

.308 Howa Sporter

.308 Howa Sporter

-

keen - Private

- Posts: 84

- South Australia

Re: Casting boolits

Aster wrote:Hey Von,

Two forum accounts? Having problems with your first one?

Hey yer! I didn't even realize that happened. Must have created two accounts. Totally weird. I like my avatar so I'll have to add that underscore in between the names & change back. Thanks for bringing that up, I had forgotten!

-

von_klitzing - Lance Corporal

- Posts: 144

- Queensland

Re: Casting boolits

All sorted mate.

I merged the few posts from your second account into the original with your avatar.

I merged the few posts from your second account into the original with your avatar.

See you on the firing line.

-

Aster - Moderator

- -

Re: Casting boolits

Moving on... Hand lubed 60 odd projectiles last night, took ages lol. The beeswax and moly combo wouldn't stay liquid for long and was too hot to touch once it was anyway. So I did it cold and it worked ok just warming up while rubbing it into the lube grooves. Will get quicker as I go I guess. I definitely need to do some reading on all the methods of lubing as this was painful!

I'm home with the kids for a couple of days so I will slowly crack the rest out

I'm home with the kids for a couple of days so I will slowly crack the rest out

-

von_klitzing - Lance Corporal

- Posts: 144

- Queensland

Re: Casting boolits

Finally have a finished product.

Saeco Redding #445 220gr SWBB, 23-25gr ADI 2205, CCI primers, and Magtech brass.

One problem is my Chamber OAL measures 1.75" yet the max COAL is 1.61". If I seat the bullet to the former measurement, the brass won't reach the crimp groove. hmmm. Will see how it turns out.

I'm heading out to do some shooting this morning.

Saeco Redding #445 220gr SWBB, 23-25gr ADI 2205, CCI primers, and Magtech brass.

One problem is my Chamber OAL measures 1.75" yet the max COAL is 1.61". If I seat the bullet to the former measurement, the brass won't reach the crimp groove. hmmm. Will see how it turns out.

I'm heading out to do some shooting this morning.

-

von_klitzing - Lance Corporal

- Posts: 144

- Queensland

Re: Casting boolits

Pay off day for all your new learnin'! Your gunna have fun! 14 thou difference in COAL isn't very much and may not make any change in accuracy. Better look for any lead stripping after the first few shots though to be safe.

There's still a few of Wile. E Coyote's ideas that I haven't tried yet.

-

Noisydad - Warrant Officer C1

- Posts: 1383

- Victoria

Re: Casting boolits

Hehe, that's .140" there Noisy. Yep I'll be keeping a keen eye out for lead deposits  though it's in a lever action so may not be so easy without gaining some attention.

though it's in a lever action so may not be so easy without gaining some attention.

-

von_klitzing - Lance Corporal

- Posts: 144

- Queensland

Re: Casting boolits

Well, turns out my loads were a huge fail. I fired one round and had a massive cloud of smoke come out the muzzle, with a really deep boom lol. 23gr of AR2205 is for Jacketed bullets, not cast lead bullets, so loaded these rounds way too hot (the cartridges and primers could take it, but it just didn't burn the powder).... I was pretty chaffed about my casts that I didn't even realize my mistaken load data. So according to ADI I should really be using AS30N or AP70N. However, AR2205 can still be used for magnum rounds, so do you think it could be possible to get an effective round with a reduced load?? Eg. For .357 magnum a cast lead bullet is loaded 4 gr lighter than the same weight factory bullet using AR2205 (see 158gr. in the table) http://www.adi-powders.com.au/handloade ... 357+Magnum

Effectively I would still like to try to use the AR2205 in this caliber so I'm not having to buy another bucket o' powder...

Also, I've been reading some people use https://www.loaddata.com/ for reference, and it's supposed to have pretty much everything you'd want on the site. Does anyone use this? Would you recommend subscribing?

Cheers.

Effectively I would still like to try to use the AR2205 in this caliber so I'm not having to buy another bucket o' powder...

Also, I've been reading some people use https://www.loaddata.com/ for reference, and it's supposed to have pretty much everything you'd want on the site. Does anyone use this? Would you recommend subscribing?

Cheers.

-

von_klitzing - Lance Corporal

- Posts: 144

- Queensland

Re: Casting boolits

Bummer

So what happens to your cast bullets with the jacketed amount of powder?

Just spits out a glob of lead does it?

So what happens to your cast bullets with the jacketed amount of powder?

Just spits out a glob of lead does it?

-

Bark - Lance Corporal

- Posts: 219

- Victoria

Re: Casting boolits

Bugger von

What's to do with your cast bullets now then? I guess you can pull them and re fill the brass? Melt and redo the bullet?

What's to do with your cast bullets now then? I guess you can pull them and re fill the brass? Melt and redo the bullet?

Henry .22LR Lever Action

.308 Howa Sporter

.308 Howa Sporter

-

keen - Private

- Posts: 84

- South Australia

Re: Casting boolits

von_klitzing wrote:

Can't fault your workmanship, they look great!

Fingers crossed for them shooting the business when you're powder charge is sorted out.

Barrett M82 .50 calibre... Ok, not really

-

Fujix - Private

- Posts: 81

- Victoria

Re: Casting boolits

Bark wrote:Bummer

So what happens to your cast bullets with the jacketed amount of powder?

Just spits out a glob of lead does it?

keen wrote:Bugger von

What's to do with your cast bullets now then? I guess you can pull them and re fill the brass? Melt and redo the bullet?

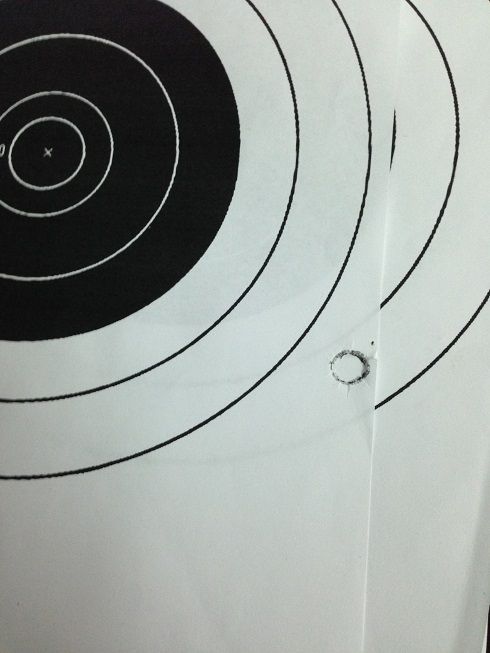

I'll be pulling the projectiles and recovering as much powder as possible, and reloading to a lower amount of grains. That one round I did fire hit the target about 6 inches from center, but I didn't recover the bullet. I'm not a fan of digging holes lol. It looks as though there were no deformities in the bullet.

I guess it's all part of the learning process, test and adjust.

Fujix wrote:

Can't fault your workmanship, they look great!

Fingers crossed for them shooting the business when you're powder charge is sorted out.

Thanks

-

von_klitzing - Lance Corporal

- Posts: 144

- Queensland

Re: Casting boolits

I'm interested to hear the result if you get back to post updates

Barrett M82 .50 calibre... Ok, not really

-

Fujix - Private

- Posts: 81

- Victoria

Re: Casting boolits

Fujix wrote:I'm interested to hear the result if you get back to post updates

Will do. That's half the fun!

-

von_klitzing - Lance Corporal

- Posts: 144

- Queensland

48 posts

• Page 1 of 2 • 1, 2