Anyone in Sydney or within a couple of hrs willing to give me a hand, happy to pay for lead and use of ur cooking pot and knowledge. Wanting to make some 440gr hard enough so it can be driven to around 1900-2000fps.

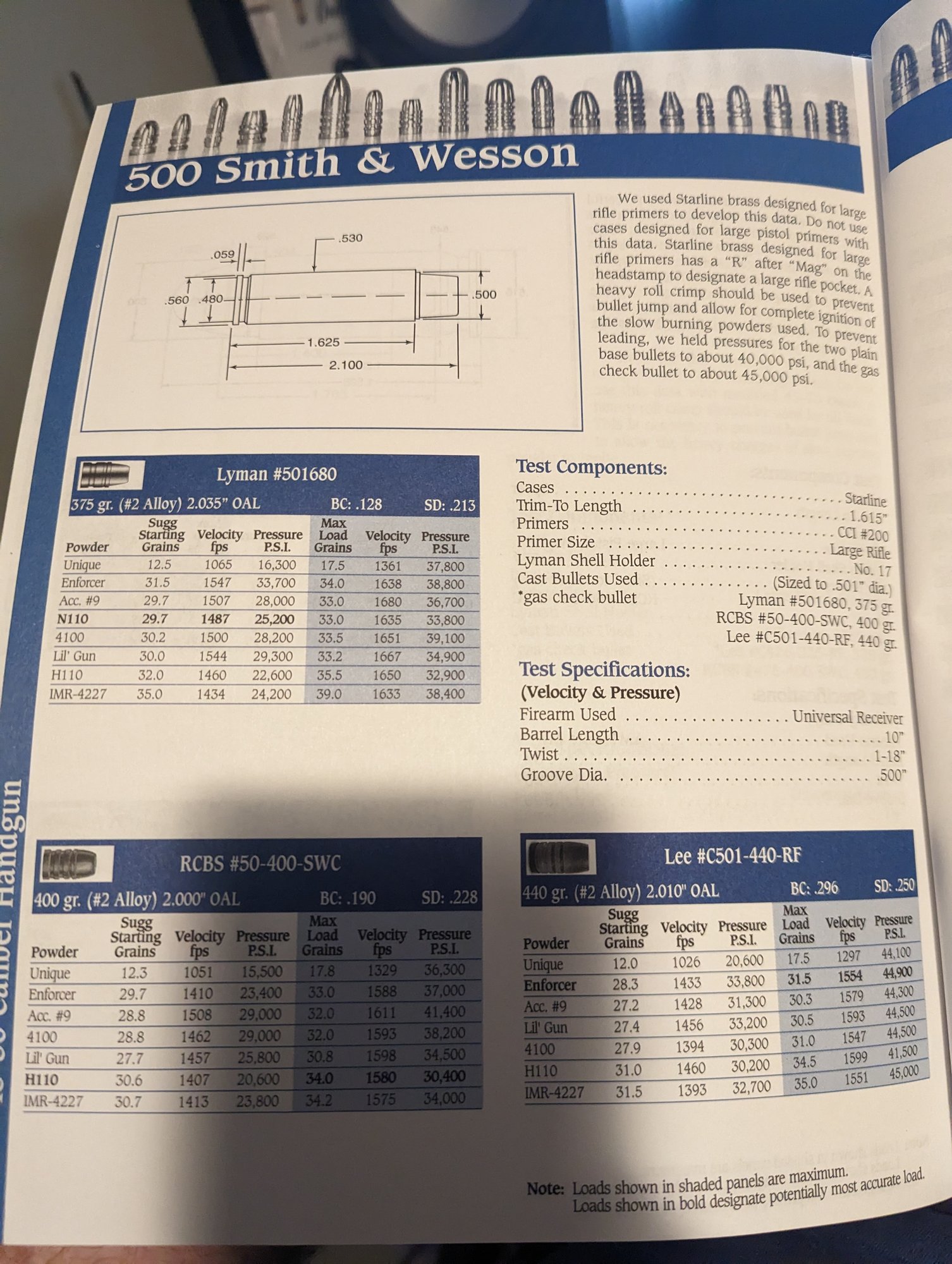

Billo wrote:With the price of availability of 50 cal projectiles not so friendly I started looking at hard casting options, my local Gunshop has the Lee 2 cavity 440gr Mould in stock, now I'm not sure hard casting is a hobby I need right now but I am keen to learn for future use.

Anyone in Sydney or within a couple of hrs willing to give me a hand, happy to pay for lead and use of ur cooking pot and knowledge. Wanting to make some 440gr hard enough so it can be driven to around 1900-2000fps.