I'm thinking about having a go at annealing.

I've read about the 'oven' method but in that over doing it you've annealed the case heads and they're too soft to use.

If you're using a more local method like a torch and you over anneal just the neck though, can you fire them to get past the too-soft stage and harden them up again or is the brass done?

Firing over-annealed necks to toughen them up

13 posts

• Page 1 of 1

Re: Firing over-annealed necks to toughen them up

Do not anneal in an oven . If it softens the base section of the case it could become dangerous . You only want to anneal the neck and shoulder area with a quick application of heat . Not soaking the whole case in an oven . Even if you do place them in a pan of water it's still not a good way . Over annealed necks will usually not cause any drama when firing as long as the main body of the case is unaffected . However what can happen is shoulders can be pushed in or stretched out by the force of neck sizing and or bullet seating if they are very soft . If that becomes an issue buy a Lee collet die and neck size with that and go very gentle with bullet seating .

- Jack V

- Sergeant

- Posts: 693

- New South Wales

Re: Firing over-annealed necks to toughen them up

Forget the oven method completely. Anyone doing it in an oven doesn't understand what they're trying to accomplish and/or doesn't know what they're doing.

Heating the brass and not exceeding the change temperature does nothing. As the article states, change begin around 495 and the rate of change depends on how much you exceed this temperature by.

If you barely went over, by so little that the case head was still in usable condition you wouldn't have done anything worthwhile for the necks. If you anneal enough to make the necks springy you've ruined the rest of the case.

If you've slightly over annealed a neck 'work' will harden it up again, that is firing and sizing. It's not possible to recover from all over-annealing though. If it's been significantly overdone at just the neck it will be too soft to use and can't be rescued.

6mmbr wrote:Brass which has been "work hardened" (sometimes referred to as "cold worked") is unaffected by temperatures (Fahrenheit) up to 482 degrees (F) regardless of the time it is left at this temperature. At about 495 degrees (F) some changes in grain structure begins to occur...

The critical time and temperature at which the grain structure reforms into something suitable for case necks is 662 degrees (F) for some 15 minutes. A higher temperature, say from 750 to 800 degrees, will do the same job in a few seconds. If brass is allowed to reach temperatures higher than this (regardless of the time), it will be made irretrievably and irrevocably too soft.

Heating the brass and not exceeding the change temperature does nothing. As the article states, change begin around 495 and the rate of change depends on how much you exceed this temperature by.

If you barely went over, by so little that the case head was still in usable condition you wouldn't have done anything worthwhile for the necks. If you anneal enough to make the necks springy you've ruined the rest of the case.

If you've slightly over annealed a neck 'work' will harden it up again, that is firing and sizing. It's not possible to recover from all over-annealing though. If it's been significantly overdone at just the neck it will be too soft to use and can't be rescued.

-

Mich - Lance Corporal

- Posts: 182

- United States of America

Re: Firing over-annealed necks to toughen them up

Jack V wrote:Do not anneal in an oven.

I wonder who started that bit of "info" circulating.

Who knows how much brass was ruined due to it.

Savage 14/114 American Classic 30-06 Springfield

Savage Axis 25-06 Remington

Savage Axis 25-06 Remington

-

Harper - Corporal

- Posts: 281

- Northern Territory

Re: Firing over-annealed necks to toughen them up

Yes I agree mate. It's a bad way to try and anneal brass . A quick application of heat from a small map gas torch is way better .

- Jack V

- Sergeant

- Posts: 693

- New South Wales

Re: Firing over-annealed necks to toughen them up

If our brass is " over annealed " then you have probably burnt the zink out ofthe brass it turning it into copper... irreversible dammage.

Try doing it n a dark room with only the flame as light. Heat the neck untill you can see the faintest glow, not nealy cherry red... literally the faintest glow you can notice, then quench it in a bucket of water to stop the heat spreading too far.

Try doing it n a dark room with only the flame as light. Heat the neck untill you can see the faintest glow, not nealy cherry red... literally the faintest glow you can notice, then quench it in a bucket of water to stop the heat spreading too far.

Gun control requires concentration and a steady hand

-

on_one_wheel - Colonel

- Posts: 3596

- South Australia

Re: Firing over-annealed necks to toughen them up

It would have to be very over anneal and for some time to burn out any zinc . The main problem is brass is too soft to reload . Either the base has become soft and it's no longer as strong as it should be to safely contain pressures or the neck shoulder area is too soft to reload properly with conventional dies or both.

If a case is just too soft at the neck and shoulder but the base and body is fine then using a Lee collet die to size it to hold a bullet and then just neck sizing for as long as you can until the case starts to stick a bit and then try a normal die to see if it's hard enough to size with expander balls but if it fails use a Redding body die instead . No neck sizing or expander ball in that type of die to crush or stretch anything .

If a case is just too soft at the neck and shoulder but the base and body is fine then using a Lee collet die to size it to hold a bullet and then just neck sizing for as long as you can until the case starts to stick a bit and then try a normal die to see if it's hard enough to size with expander balls but if it fails use a Redding body die instead . No neck sizing or expander ball in that type of die to crush or stretch anything .

- Jack V

- Sergeant

- Posts: 693

- New South Wales

Re: Firing over-annealed necks to toughen them up

More Than Just The Gun

-

chacka - Corporal

- Posts: 331

- South Australia

Re: Firing over-annealed necks to toughen them up

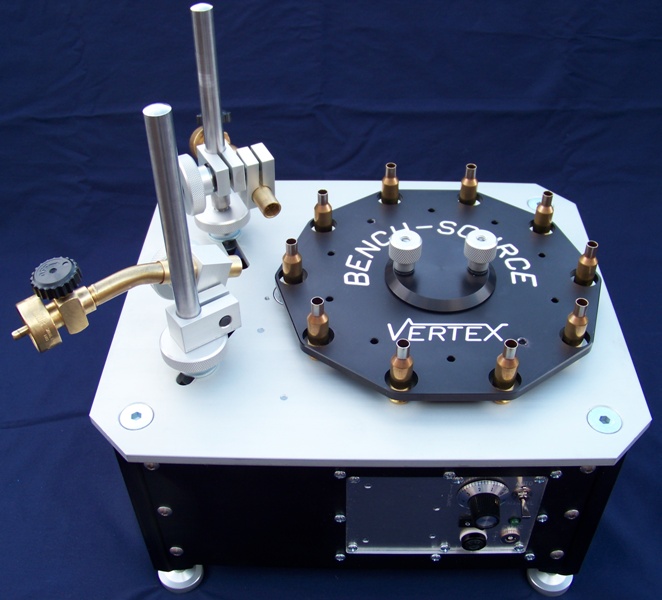

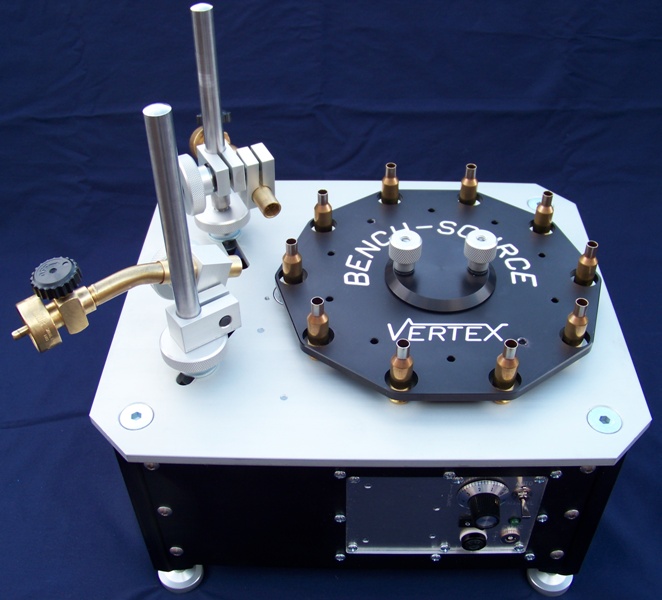

I use one of these to anneal the bigger cases, 650F is apparently the key number to aim for at the neck and not higher then 400-450F at the base. I use 650 & 450F Tempilaq paint to calibrate the amount of time for each different case then record the settings. I have 2 top plates which cover virtually every round from .17 Remington up to 50 BMG. Any other method is a pure waste of time as you may over heat the base or under heat the neck. Overheating the base could have fatal consequences due to case failure, maybe not so dangerous on a .204 but a head separation on a 50 will definitely leave a mark. These machines are not cheap at around $600 delivered but how much is your life worth?

Tempilaq http://www.tempil.com/products/tempilaq-indicating-liquids/

Sometimes you have to ask the question "Am I smarter then the guy who designed this?" Often the answer will be "No" so I follow their methods cause they are tried and tested which saves me time, money and pain .

.

Tempilaq http://www.tempil.com/products/tempilaq-indicating-liquids/

Sometimes you have to ask the question "Am I smarter then the guy who designed this?" Often the answer will be "No" so I follow their methods cause they are tried and tested which saves me time, money and pain

How's my posting?

Complaints, Concerns - 13 11 14

Complaints, Concerns - 13 11 14

-

brett1868 - Lieutenant Colonel

- Posts: 3017

- New South Wales

Re: Firing over-annealed necks to toughen them up

brett1868 wrote:I use one of these to anneal the bigger cases, 650F is apparently the key number to aim for at the neck and not higher then 400-450F at the base. I use 650 & 450F Tempilaq paint to calibrate the amount of time for each different case then record the settings. I have 2 top plates which cover virtually every round from .17 Remington up to 50 BMG. Any other method is a pure waste of time as you may over heat the base or under heat the neck. Overheating the base could have fatal consequences due to case failure, maybe not so dangerous on a .204 but a head separation on a 50 will definitely leave a mark. These machines are not cheap at around $600 delivered but how much is your life worth?

Sometimes you have to ask the question "Am I smarter then the guy who designed this?" Often the answer will be "No" so I follow their methods cause they are tried and tested which saves me time, money and pain.

True nice accurate machine and they do work well, especially for someone doing as much reloading as yourself, but when tipping them over in a pan of water stops working for me(and it does work) i'll just shoot them until they crack and buy new ones. But I am the king of stingy reloading.

Mind you I am never likely to have to anneal anything more than .308 and .303, I don't bother with the win mag and can't speak for the bigger calibres.

- Warrigul

- Warrant Officer C2

- Posts: 1103

- -

Re: Firing over-annealed necks to toughen them up

Warrigul, nothing wrong with being thrifty with the coin. Invest $25 in Tempilaq 650F to work out how many seconds you need under the torch to anneal it properly as nothing is gained by under annealing apart from wasted time & money. I don't bother annealing the smaller stuff, I just shoot it, check and scrap any cases that look suspect.

How's my posting?

Complaints, Concerns - 13 11 14

Complaints, Concerns - 13 11 14

-

brett1868 - Lieutenant Colonel

- Posts: 3017

- New South Wales

Re: Firing over-annealed necks to toughen them up

brett1868 wrote:Warrigul, nothing wrong with being thrifty with the coin. Invest $25 in Tempilaq 650F to work out how many seconds you need under the torch to anneal it properly as nothing is gained by under annealing apart from wasted time & money. I don't bother annealing the smaller stuff, I just shoot it, check and scrap any cases that look suspect.

The biggest issue with hand annealing is the wasted cases when you over do them(not as big an issue now I have collett dies), the only way to get them 100% right manually is to wait for a full moon when the wind is blowing from the East or sacrifice a goat first.

- Warrigul

- Warrant Officer C2

- Posts: 1103

- -

Re: Firing over-annealed necks to toughen them up

brett1868 wrote:I use one of these to anneal the bigger cases

You just had to come along and one-up silvers awesome DIY one didn't you

More Than Just The Gun

-

chacka - Corporal

- Posts: 331

- South Australia

13 posts

• Page 1 of 1